SOLUTIONS / ENGINEERED SYSTEMS / HYDRAULIC TECHNICAL DATA

Hydrotech isn't just a distributor of quality industrial parts. We staff a full engineering department with experienced experts ready to design, assemble and integrate full system solutions.

Hydrotech isn't just a distributor of quality industrial parts, We staff a full engineering department with experienced experts ready to design, assemble and integrate full system solutions.

Horsepower for driving a pump:

For every 1 hp of drive, the equivalent of 1 gpm @ 1500 psi can be produced.

Horsepower for idling a pump:

To idle a pump when it is unloaded will require about 5% of it's full rated power

Wattage for heating hydraulic oil:

Each watt will raise the temperature of 1 gallon of oil by 1° F. per hour.

Flow velocity in hydraulic lines:

Pump suction lines 2 to 4 feet per second, pressure lines up to 500 psi - 10 to 15 ft./sec., pressure lines 500 to 3000 psi - 15 to 20 ft./sec.; all oil lines in air-over-oil systems; 4 ft./sec.

| Variable | Word Formula w/ Units | Simplified Formula |

| Fluid Pressure - P | (PSI) = Force (Pounds) / Area (Sq. In.)

| P = F / A

|

| Fluid Flow Rate - Q | GPM = Flow (Gallons) / Unit Time (Minutes)

| Q = V / T

|

| Fluid Power in Horsepower - HP | Horsepower = Pressure (PSIG) x Flow (GPM)/ 1714

| HP = PQ / 1714

|

| Variable | Word Formula w/ Units | Simplified Formula |

| Cylinder Area - A | ( Sq. In.) = π × Radius (inch)2

| A = π × R2

|

(Sq. In.) = π × Diameter (inch)2 / 4

| A = π × D2 / 4

| |

| Cylinder Force - F | (Pounds) = Pressure (psi) × Area (sq. in.)

| F = P × A

|

| Cylinder Speed - v | (Feet / sec.) = (231 × Flow Rate (gpm)) / (12 × 60 × Area)

| v = (0.3208 × gpm) / A

|

| Cylinder Volume Capacity - V | Volume = π × Radius2 × Stroke (In.) / 231

| V = π × R2 × L / 231 (L = length of stroke) |

| Cylinder Flow Rate - Q | Volume = 12 × 60 × Velocity (Ft./Sec.) × Net Area(In.)2 / 231

| Q = 3.11688 × v × A

|

| Fluid Motor Torque - T | Torque (in. lbs.) = Pressure (psi) × disp. (in.3 / rev.) / 6.2822

| T = P × d / 6.2822

|

Torque = HP × 63025 / RPM

| T = HP × 63025 / n

| |

Torque = Flow Rate (GPM) × Pressure × 36.77 / RPM

| T = 36.77 × Q × P / n

| |

| Fluid Motor Speed - n | Speed (RPM) = (231 × GPM) / Disp. (in.)3

| n = (231 × GPM) / d

|

| Fluid Motor Horsepower - HP | HP = Torque (in. lbs.) × rpm / 63025

| HP = T × n / 63025

|

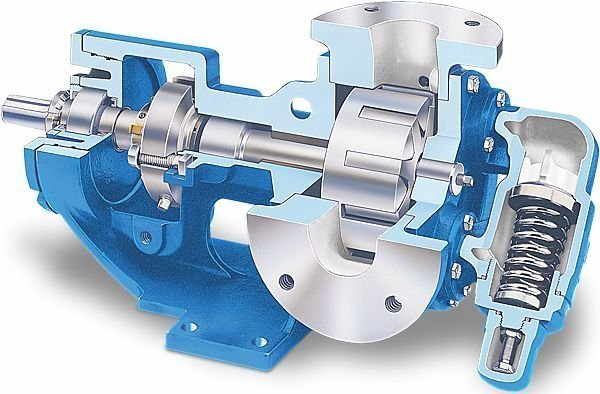

| Variable | Word Formula w/ Units | Simplified Formula |

| Pump Output Flow - GPM | GPM = (Speed (rpm) × disp. (cu. in.)) / 231

| GPM = (n ×d) / 231

|

| Pump Input Horsepower - HP | HP = GPM × Pressure (psi) / 1714 × Efficiency

| HP = (Q ×P) / 1714 × E

|

| Pump Efficiency - E | Overall Efficiency = Output HP / Input HP

| EOverall = HPOut / HPIn X 100

|

Overall Efficiency = Volumetric Eff. × Mechanical Eff.

| EOverall = EffVol. × EffMech.

| |

| Pump Volumetric Efficiency - E | Volumetric Efficiency = Actual Flow Rate Output (GPM) / Theoretical Flow Rate Output (GPM) × 100

| EffVol. = QAct. / QTheo. X 100

|

| Pump Mechanical Efficiency - E | Mechanical Efficiency = Theoretical Torque to Drive / Actual Torque to Drive × 100

| EffMech = TTheo. / TAct. × 100

|

| Pump Displacement - CIPR | Displacement (In.3 / rev.) = Flow Rate (GPM) × 231 / Pump RPM

| CIPR = GPM × 231 / RPM

|

| Pump Torque - T | Torque = Horsepower × 63025 / RPM

| T = 63025 × HP / RPM

|

Torque = Pressure (PSIG) × Pump Displacement (CIPR) / 2π

| T = P × CIPR / 6.28

|

OUR PURPOSE

American industry has never enjoyed more opportunity than it does today – or faced more challenges. Hydrotech is here to help you compete, evolve, lead and win with superior solutions in fluid power, automation, service & repair and connected technologies.