SUN HYDRAULICS

FDBACBE

$431.10 USD

Tags:

- SUN HYDRAULICS

- Material:FDBACBE

- Model:FDBA-CBE

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

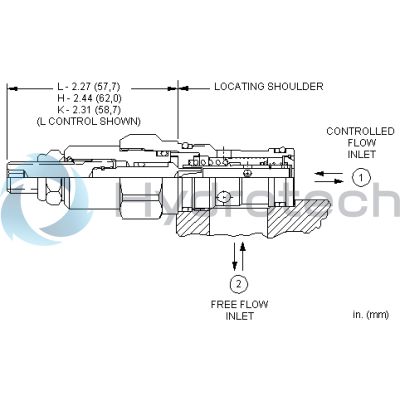

The Sun Hydraulics FDBACBE (FDBACBE) is a fully adjustable, pressure-compensated flow control valve designed for precise flow regulation in both meter-in and meter-out applications, especially where there are significant pressure fluctuations. This model features an integral high-capacity check valve that allows for unrestricted flow from port 2 to port 1. The flow control cartridges are interchangeable in terms of function and physical dimensions, though the extension dimensions from the mounting surface may vary. The valve's balanced adjustment mechanism facilitates easy adjustments even under high-pressure conditions, while its sharp-edged orifice design minimizes flow variations due to changes in viscosity. The FDBACBE model has a minimum leakage rate of 0.1 gpm when the adjustment mechanism is fully closed. It is compatible with systems using phosphate ester fluids but should not be used with petroleum-based fluids due to potential seal damage. The cartridge fits into a T-13A cavity, belongs to Series 1, and has a capacity of 6 gpm with a maximum operating pressure of 5000 psi. The adjustment can be made over 5.5 counterclockwise turns from fully closed to fully open. Key dimensions include a valve hex size of 7/8 inches and an installation torque range of 30-35 lbf ft. The adjustment screw requires an internal hex size of 5/32 inches, while the locknut has a hex size of 9/16 inches with a torque specification between 80-90 lbf in. Weighing just .40 lb, this model comes with Viton seals as part of its seal kit options.

The Sun Hydraulics FDBACBE (FDBACBE) is a fully adjustable, pressure-compensated flow control valve designed for precise flow regulation in both meter-in and meter-out applications, especially where there are significant pressure fluctuations. This model features an integral high-capacity check valve that allows for unrestricted flow from port 2 to port 1. The flow control cartridges are interchangeable in terms of function and physical dimensions, though the extension dimensions from the mounting surface may vary. The valve's balanced adjustment mechanism facilitates easy adjustments even under high-pressure conditions, while its sharp-edged orifice design minimizes flow variations due to changes in viscosity. The FDBACBE model has a minimum leakage rate of 0.1 gpm when the adjustment mechanism is fully closed. It is compatible with systems using phosphate ester fluids but should not be used with petroleum-based fluids due to potential seal damage. The cartridge fits into a T-13A cavity, belongs to Series 1, and has a capacity of 6 gpm with a maximum operating pressure of 5000 psi. The adjustment can be made over 5.5 counterclockwise turns from fully closed to fully open. Key dimensions include a valve hex size of 7/8 inches and an installation torque range of 30-35 lbf ft. The adjustment screw requires an internal hex size of 5/32 inches, while the locknut has a hex size of 9/16 inches with a torque specification between 80-90 lbf in. Weighing just .40 lb, this model comes with Viton seals as part of its seal kit options.

Fully adjustable, pressure-compensated flow controls with reverse-flow check provide precise flow regulation for meter-in or meter-out applications where there may be wide pressure fluctuations. They are infinitely adjustable from nearly closed up to the maximum flow. An integral high-capacity check valve provides unrestricted flow from port 2 to port 1.

- All 2-port flow control cartridges are physically and functionally interchangeable (i.e. same flow path, same cavity for a given frame size). However, cartridge extension dimensions from the mounting surface may vary.

- A balanced adjustment mechanism allows for easy adjustment even at high pressures.

- The sharp-edged orifice design minimizes flow variations due to viscosity changes.

- Minimum leakage is .1 gpm (0,4 L/min) when the adjustment mechanism is turned to the shut-off position.

- Cartridges with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

| Cavity | T-13A |

| Series | 1 |

| Capacity | 6 gpm23 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Adjustment - Number of Counterclockwise Turns - Fully Closed to Fully Open | 55 |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Adjustment Screw Internal Hex Size | 5/32 in.4 mm |

| Locknut Hex Size | 9/16 in.15 mm |

| Locknut Torque | 80 - 90 lbf in.9 - 10 Nm |

| Model Weight | .40 lb0,20 kg |

| Seal kit - Cartridge | Viton: 990-010-006 |

Show FAQ